A Conversation about Innovation, Sustainability and the Future of the Packaging Industry

With sustainable digitalization, Kampf GmbH is breaking new ground. As an active member of the R-Cycle initiative, the Jagenberg Group company is driving the development of digital product passports for the plastic packaging industry.

We spoke with Maik Krüger, Head of Business Development at Kampf, about the forward-looking significance of the initiative and technology

Mr. Krüger, what exactly is R-Cycle? Please briefly outline the initiative.

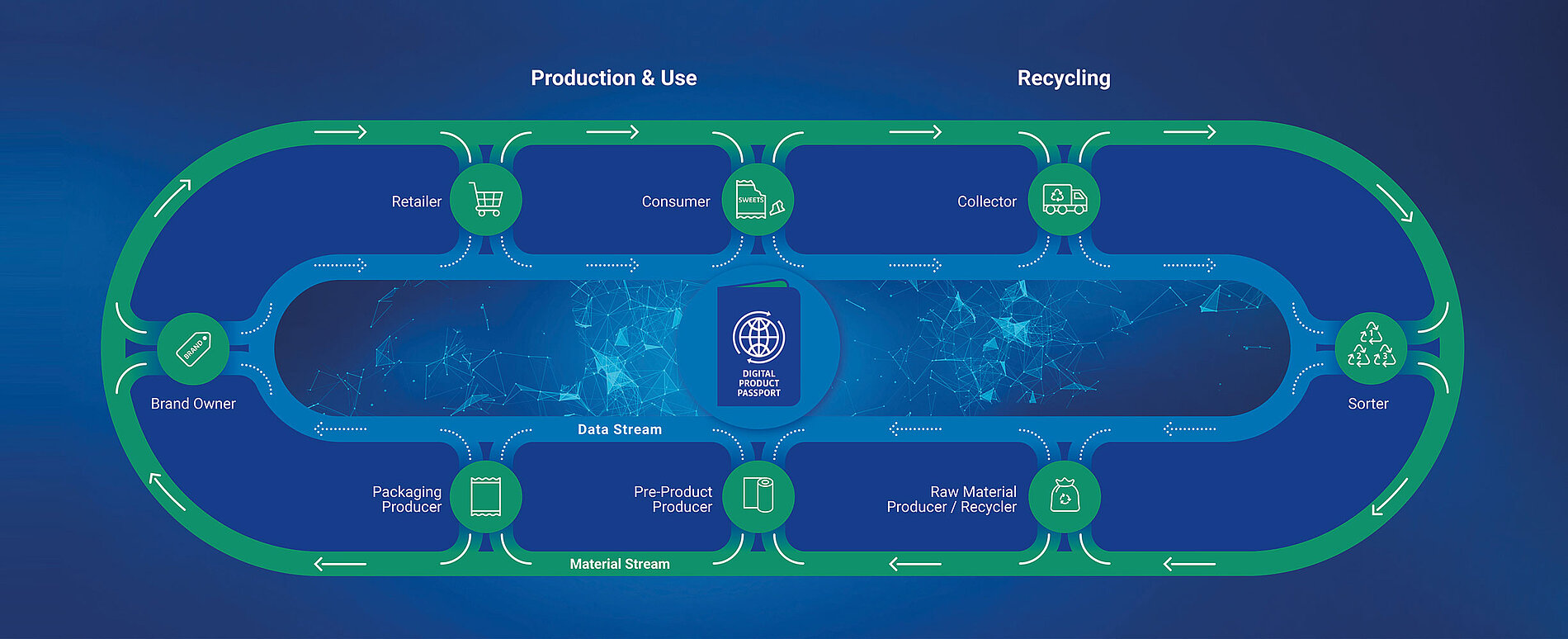

R-Cycle is a cross-industry initiative. It creates an open and globally applicable standard for the traceability of plastic packaging in industry. At its core, it's about providing a standardized data infrastructure and enabling digital product passports. This allows recycling-relevant information – such as material composition or processing – to be captured and shared along the entire value chain. This is a central building block for a functioning circular economy in the plastics sector. By creating a data-based foundation, materials can be recycled efficiently and with high quality.

R-Cycle is a cross-industry initiative of over 50 companies and institutions from industry and research that develops an open standard for the traceability of plastic products. Through digital product passports, recycling-relevant information is made available along the entire value chain worldwide – an important building block for a functioning circular economy. As a member of the Steering Committee and through regular participation in workshops and working groups, Kampf actively shapes the future of this forward-looking technology.

Contact: More information about the R-Cycle initiative and Kampf‘s engagement can be found on our website or contact us directly for specific questions about digital product passports and sustainable machine solutions.

You speak of a "data-based foundation" for the circular economy. What specifically does circular economy mean for you as a machine manufacturer?

For me, circular economy means using resources as efficiently as possible throughout their entire lifecycle. So not just using them once, but ideally multiple times. The goal is to keep materials in the economic cycle for as long as possible, whether through reuse, refurbishment, or recycling. This requires a high degree of transparency, particularly about the properties and origins of materials. Only when this information is available can modern recycling processes work effectively. R-Cycle makes a crucial contribution to this by making the necessary data available in digital form. This is what makes true circularity possible in the first place.

That sounds quite theoretical at first. What does it look like in practice – how has Kampf integrated R-Cycle into its own processes?

Kampf can integrate R-Cycle directly into its machines: We capture relevant production and machine data and feed it into the digital product passport, the so-called DPP. This information then accompanies the product along the value chain. At the same time, our systems are also capable of reading data from the DPP and working with it. For example, customers can derive optimal machine settings that increase quality and optimize material usage. This bidirectional use – writing and reading DPP data – opens up new possibilities for our partners in terms of transparency, process reliability, and resource efficiency in production, even across company boundaries. This way, we not only contribute to the circular economy but also to the digitalization of industry.

"Bidirectional use" sounds like a tangible competitive advantage. What concrete benefits do you see for Kampf as a company, Mr. Krüger?

We see several advantages for us. As a pioneer in implementing digital product passports, we position ourselves as an innovative company. At the same time, we drive technologies that enable our customers to achieve real efficiency gains – for example, through optimized production or waste reduction.

A major advantage also lies in the intelligent linking of machine data with the digital product passport. This creates a new data base that ensures transparency and measurably improves processes along the value chain.

Furthermore, collaboration in the network opens up the possibility for us to identify current challenges together with other companies. In concrete use cases, we can develop very practical solutions. This collaborative approach is particularly valuable for us because it enables innovation in a real, industrial context.

You speak of practical use cases. Are there already successful application cases that underscore the success of the R-Cycle initiative?

R-Cycle looks back on important milestones – with a strong community and practical successes. The special collaboration in the R-Cycle community connects industry and research. 50 leading companies and universities are jointly developing the R-Cycle standard further. With the clear goal of strengthening the circular economy in a practical way.

A concrete success is the development of the Plastics Traceability Guideline with GS1. This represents an important milestone for making packaging data interoperably usable along global supply chains.

Particularly relevant for us as Kampf is the joint use case with our partner Brückner: As members of the R-Cycle community, both companies together show how the system can be seamlessly integrated into Industry 4.0 applications – an important step toward digitalization of production.

GS1 and the Plastics Traceability Guideline

GS1, short for Global Standards One, is a globally leading non-profit organization. Since 1974, it has been developing global standards for the supply chain. These include, among others, the barcodes that enable automatic checkout worldwide.

With the "GS1 Guideline for Circular Plastics Traceability," the organization has created a guideline for data exchange in the circular economy for plastics. This promotes more efficient recycling processes and facilitates compliance with regulatory requirements.

Let's take a step back: How does this digital product passport actually work concretely? That surely sounds very abstract to many people.

The digital product passport is basically a structured data set. It contains all recycling-relevant information about a product – for example, material types, additives used, or certain parameters from the manufacturing process. This information is collected along the entire value chain, processed in a standardized way, and made available in machine-readable form. This is made possible by the use of modern marking technologies as well as cloud-based systems. The big advantage: relevant data accompanies the product throughout its entire lifecycle – a crucial prerequisite for functioning recycling processes and true circular economy.

That sounds very complex. How does the collaboration with the R-Cycle team work in practice? Are you more of a customer or partner?

The collaboration with the R-Cycle team is really very open and partnership-based. We are in close exchange – whether through workshops, regular jour fixes, or in the steering committee. In doing so, we bring in our perspective as machine manufacturers. This is particularly important so that technical requirements and possibilities are considered early on. At the same time, we benefit enormously from the knowledge and input of other R-Cycle members and experts who come from very different industries. This interdisciplinary collaboration is real added value for us because it helps us think outside our own box and develop holistic solutions for the circular economy together. Ultimately, the entire network thrives on everyone contributing their strengths – that's exactly what makes R-Cycle so valuable.

This network work fits well with current sustainability developments. To what extent does R-Cycle contribute to Kampf's sustainability goals?

R-Cycle contributes to our sustainability goals in multiple ways. On one hand, by integrating the digital product passport, we improve the availability and quality of relevant data – an important aspect within our ESG strategy. At the same time, we actively promote digitalization as a key technology for a future-oriented circular economy.

The combination of technological progress and sustainable business practices is a central approach for us, and R-Cycle provides a valuable contribution here that we want to strategically expand further.

You speak of "strategically expanding further." Where is the journey going? What are your concrete future plans for collaboration with R-Cycle?

Our goal is to further expand the integration of R-Cycle into our machine solutions. We will develop new application areas – particularly in the field of data-based process optimization. A concrete next step is the presentation of a so-called demonstrator at the Plastics Fair 2025. It shows a real R-Cycle application case. With this, we not only demonstrate our technological competence but also provide an outlook on the potential that lies in combining machine technology and digital product passport – for more transparency, efficiency, and sustainability along the entire value chain.

That's a nice outlook for K 2025. Allow us one final personal question, Mr. Krüger: You deal so intensively with recycling and sustainability professionally – to what extent do you pay attention to these topics in your private environment?

In my private life, I try to handle resources as responsibly as possible. For me, this mainly means avoiding single-use products as much as possible and deliberately buying durable products, preferably with recycled content when possible.

Another important aspect for me is awareness of packaging waste and transport routes. For example, we as a family participate in community-supported agriculture directly at our place of residence. The food is not only seasonal and fresh but also completely unpackaged. That's maximum waste reduction and the principle simultaneously strengthens our regional agriculture. For me, this is a thoroughly sustainable approach that shows well how resource conservation can be concretely implemented in everyday life.

Mr. Krüger, thank you very much for the fascinating insights and the friendly conversation.